Seamless Integration

At Titan AV, we recognise the uniqueness of every AV setup. That's why we provide custom solutions meticulously designed to meet your specific needs.

Our team of experts works closely with you to create bulk solutions that seamlessly integrate with your equipment.

Bulk Orders for Custom Solutions

As a small team with high standards, we currently focus on fulfilling bulk orders (30+ units) for our custom solutions to ensure financial viability.

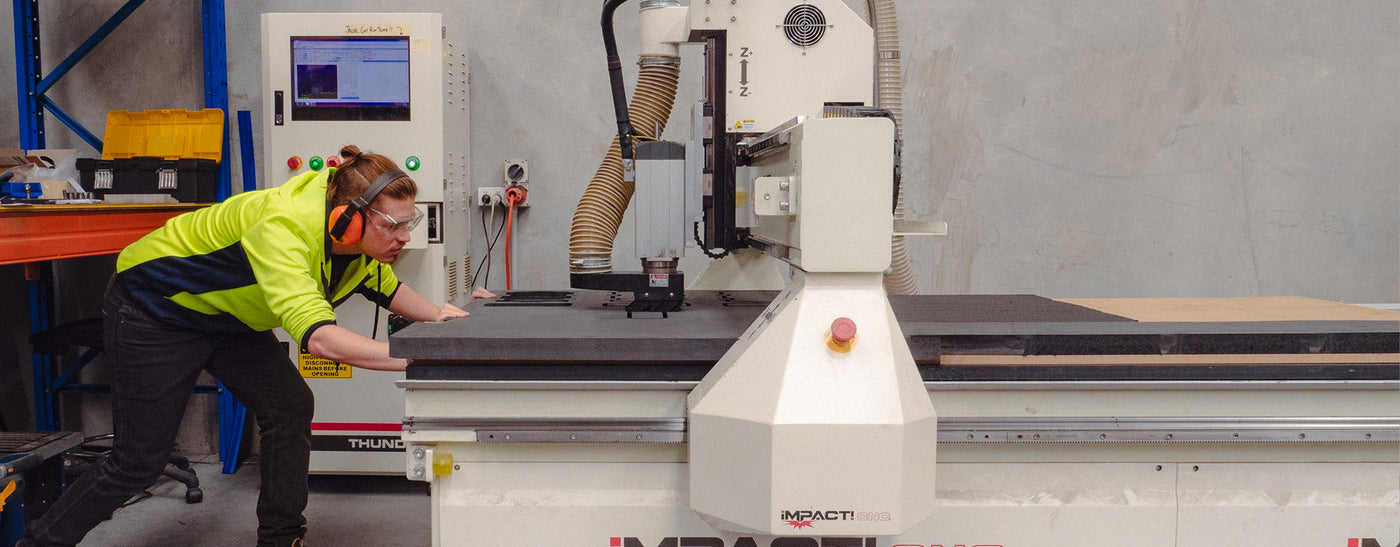

We understand the need for scalability and offer the flexibility to produce large quantities without compromising on quality. Our advanced CNC manufacturing ensures consistent excellence in every piece, whether it's custom foam inserts or precision components. Trust Titan AV for premium, custom-made AV solutions, crafted in bulk to meet your needs.

Custom Cases for VR Gear

Challenge: Fire Safety Training Solutions sought customised cases to safeguard and recharge their virtual reality headsets. They needed a charging system integrated into the case for convenient recharging on the go.

Solution: Titan AV created a one of a kind, CNC machine cut, foam insert with a built-in charging system. Its innovative design features layered foam that cleverly conceals cables within the cases for hassle-free charging and superior protection.

Why Choose Titan AV?

At Titan AV, we take immense pride in the details. With 20+ years in the Australian AV industry, our innovations solve problems, save time, and outlast. From the meticulous design phase to the final product, we indulge in our obsession with precision & attention to detail.

We're not just perfectionists; we're on a mission to ensure every piece of gear we create meets our commitment to excellence.

Want something custom made?

Reach out to us, and together, we'll make your vision a reality.

Please note: to make custom builds financially viable, we primarily focus on large quantity orders (10+ units).

{formbuilder:NzU5OTA=}

FAQs

How does CNC manufacturing work?

How does CNC manufacturing work?

CNC manufacturing involves the use of computer-numerical-controlled machines to automate the fabrication process. If you've never come across a CNC machine before, picture this: it sounds like a roaring jet engine, resembles those massive air hockey tables, and works as a computerized wizard guiding a router for ultra-precise (often down to fractions of a millimeter) cutting. These machines follow precise instructions to cut, shape, and carve materials into desired forms.

What is the process for custom CNC orders?

What is the process for custom CNC orders?

To provide customised solutions, we follow a well-defined process.

- Customers provide their specific requirements, we thoroughly review the request & gather all necessary details.

- Based on the information received, we prepare and send a custom quote to the customer. Once approved, our experienced team swings into action.

- Our team creates a precise digital design aligned with the customer's requirements, which is then loaded into our advanced CNC machine.

- The CNC machine employs its precision cutting capabilities to fabricate the desired shapes and cavities from high-quality materials like EVA foam, EPE foam, aluminum, or plywood.

- The finished products undergo a thorough inspection to ensure quality and accuracy, followed by meticulous cleaning and preparation for packaging.

- Finally, the fully custom fit solutions are delivered to the customer.

Throughout the process, we maintain close communication with our customers to ensure their satisfaction and address any queries or concerns that may arise.

How long do custom projects take?

How long do custom projects take?

At Titan AV, we understand the importance of timely solutions. While some jobs can be completed in just a matter of days, please note that there is no standard wait time. As a 2-person team dedicated to crafting your custom gear, we appreciate your patience throughout the process. We continually work to enhance our efficiency, ensuring the quality of your custom gear is never compromised. Your satisfaction is our top priority, and we're committed to delivering exceptional results.

Do you supply cases for custom foam inserts?

Do you supply cases for custom foam inserts?

Absolutely! Alongside our custom foam inserts, Titan AV supplies road cases and waterproof plastic cases in various sizes, ensuring optimal protection for your AV equipment. From compact to large options, our high-quality cases perfectly complement our foam inserts, offering comprehensive solutions for AV professionals and enthusiasts.

Do you salvage CNC off cuts?

Do you salvage CNC off cuts?

Yes, we salvage whatever CNC off cuts we can to minimise waste and promote sustainability in our manufacturing process. Some of the leftover foam is used in our packaging or donated to a local Brisbane recycling initiative, Reverse Garbage. Whilst not everything can be salvaged, we strive to utilise the materials efficiently and reduce unnecessary waste wherever possible.